Rock Bridge Automotive Repair

Brake Repairs And Brake Component Repairs

Things Always Go Better For You If You Can Stop!

Disc Brake Special!

New high quality pads and two new brake rotors installed for $240.00. This deal applies for 99% of all cars and trucks. All repair work is done by qualified technicians.

Read moreDrum Brake Repairs

Rock Bridge Automotive Repair is your source for drum brake repairs in Gallatin, Tennessee. We repair all types of drum brakes, (and there are a lot of them).

Read moreAnti-Lock Brake Repairs

Though many repair shops don't like to repair Anti-Lock Braking systems, we repair them every day. We have the latest tools and tons of experience.

Read moreGreat Brakes Are No Accident

The single most important system in the car is the braking system. We are automotive brake specialists. (You can view some of my brake certifications in the office with the rest of the certifications. Anyone that works for me either already has, or definitely will be, ASE certified for brake repairs). We repair all aspects of the braking system including: brake fluid reservoirs, brake master cylinders, brake wheel cylinders, brake shoes, brake pads, brake rotors, brake calipers, brake lines and hoses, brake proportioning valves, ABS braking systems and more.

The single most important system in the car is the braking system. We are automotive brake specialists. (You can view some of my brake certifications in the office with the rest of the certifications. Anyone that works for me either already has, or definitely will be, ASE certified for brake repairs). We repair all aspects of the braking system including: brake fluid reservoirs, brake master cylinders, brake wheel cylinders, brake shoes, brake pads, brake rotors, brake calipers, brake lines and hoses, brake proportioning valves, ABS braking systems and more.

We repair every component of all of the different types of braking systems available for vehicles. This page was written to provide you with a basic concept of the components used in vehicle braking systems.

Cable brakes

Horse carriages used were the first vehicles to use brakes. They were either friction devices direct to the tire, or cable operated brake systems on the later models. The first cars and trucks used cable operated braking systems. You had to be tough in order to slow the vehicle down! Cable operated brakes required the user to apply way too much force to slow the vehicle down. So much force was applied to the brake pedal that it was not uncommon to bend the pedal over time!

Horse carriages used were the first vehicles to use brakes. They were either friction devices direct to the tire, or cable operated brake systems on the later models. The first cars and trucks used cable operated braking systems. You had to be tough in order to slow the vehicle down! Cable operated brakes required the user to apply way too much force to slow the vehicle down. So much force was applied to the brake pedal that it was not uncommon to bend the pedal over time!

I remember watching old shows with my father. The old car on TV slid to a stop. My father said, “That car has been fitted with hydraulic brakes. I drove those cars and you could bend the brake pedal to the floor and that car still wouldn't stop!” Most vehicles today use cable brakes only for the parking brake. (Such as the ones shown on the left).

Hydraulic brakes

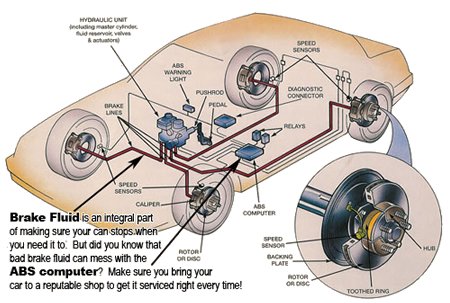

All modern vehicles us some form of hydraulic brakes. In a hydraulic braking system brake fluid is transferred from one cylinder to another carrying a force. This means that you apply force to one cylinder, (the master cylinder), the pressure generated by the master cylinder is transferred to the other braking components. Here is a diagram of a typical braking system. The hydraulic braking system generally delivers about 1,200 psi, (pounds per square inch) to the wheel brake components during a panic stop. The hydraulic braking system , combined with a brake booster, delivers so much pressure that the manufacturers began using devices to keep the wheels from locking up. You can read about those devices on this page as well.

Brake Booster

As cars began getting more luxury items like power steering, heating, and air conditioning someone decided that car should start using vacuum operated power boosters for the brakes. Brake booster first appeared for use on trucks and other large vehicles. Then they began to be offered as another luxury device in the nicer vehicles at first, (with the lower priced vehicles using manual brakes). As cars began to advertise their stopping distances however, brake boosters began to be standard equipment on almost all cars sold in the United States. Today many cars are turbocharged or supercharged which creates issues using vacuum brake boosters. Many of these cars use either hydroboost brake boosters or electric brake boosters. You can read more about brake boosters here.

As cars began getting more luxury items like power steering, heating, and air conditioning someone decided that car should start using vacuum operated power boosters for the brakes. Brake booster first appeared for use on trucks and other large vehicles. Then they began to be offered as another luxury device in the nicer vehicles at first, (with the lower priced vehicles using manual brakes). As cars began to advertise their stopping distances however, brake boosters began to be standard equipment on almost all cars sold in the United States. Today many cars are turbocharged or supercharged which creates issues using vacuum brake boosters. Many of these cars use either hydroboost brake boosters or electric brake boosters. You can read more about brake boosters here.

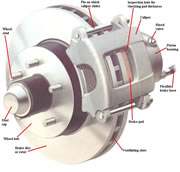

Disc Brakes

Disc brakes have been around since 1890. The first examples did not perform well and disc brakes did not get popular for use on cars and trucks until the 1950's. The designs have gotten better and better since then and currently over 98% of all cars and trucks on the road use some form of disc brake. (Many vehicles still use disc brakes on the front and drum brakes on the rear). Because disc brakes LOOK simple many people will tell you that they can replace your disc brakes for you. Don't fall for it! When non-professional installers assemble disc brakes the national average mileage for the repair is less than 20,000 mile! If you would like to know more about disc brake systems and disc brake repairs click here.

Drum Brakes

For the last hundred and fifty years cars and trucks have been using drum brakes. However, if you ask automotive technicians, (especially younger ones) less than half of the technicians tested in a recent poll knew how to properly replace or service drum brakes! I have serviced thousands of vehicles with drum brakes. I am fully certified to service or replace all types of brakes. There are many small pieces for a drum braking system and they each must function correctly and lubricated properly in order for the system to operate correctly. You can learn more about our drum brake repairs and about drum brakes in general by clicking here.

Braking Pressure And Balance Controls

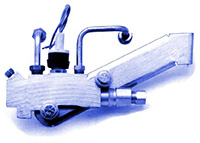

With the advances made from hydraulic brakes, the braking system became very powerful. Engineers began coming up with different ways to control wheel lock-up. The very first designs were simple proportioning valves like the one on the left. Because rear brakes in many cars were drum brake type and the front brakes were disc type brakes, the braking systems acted differently from the input of the master cylinder. Because the disc brake's pads were very close to the brake rotor they tend to start applying before the drum brake shoes that had to travel further. Engineers used a simple brake proportioning valve. to control this. The brake proportioning valve restricts fluid from traveling to the front brakes until there is pressure in the rear brakes first. Once there is pressure in the rear brake cicuit the mechanism within the valve begins to transfer more pressure to the front brakes and restrict the pressure to the rear brakes. (Weight transfers to the front wheels so they need the greater braking force.) Brake proportioning valves are present in millions of cars but there are literally thousands of technicians who do not understand them.

With the advances made from hydraulic brakes, the braking system became very powerful. Engineers began coming up with different ways to control wheel lock-up. The very first designs were simple proportioning valves like the one on the left. Because rear brakes in many cars were drum brake type and the front brakes were disc type brakes, the braking systems acted differently from the input of the master cylinder. Because the disc brake's pads were very close to the brake rotor they tend to start applying before the drum brake shoes that had to travel further. Engineers used a simple brake proportioning valve. to control this. The brake proportioning valve restricts fluid from traveling to the front brakes until there is pressure in the rear brakes first. Once there is pressure in the rear brake cicuit the mechanism within the valve begins to transfer more pressure to the front brakes and restrict the pressure to the rear brakes. (Weight transfers to the front wheels so they need the greater braking force.) Brake proportioning valves are present in millions of cars but there are literally thousands of technicians who do not understand them.

Several manufacturers went a step further by adding a rod and a rear brake proportioning valve to the rear of the vehicle. The image to the left is an example of that from Toyota. The rear brake proportioning valve limited the amount of brake fluis that could travel to the rear brakes as the vehicle tilted forwards. (peiods of heavy braking) The idea behind this was good because it compensated for worn shock absorbers and vaying loads. I can't tell you how many technicians have asked me what those rods were for. When I first saw them on cars in the 1970's it took me about 2 minutes to figure out what they did. You can clearly see the brake lines coming into them and the lines leading out to the rear wheel. There is a rod which leads to the body which travels with the body. These devices went a step further in controlling the difference between the front brakes and the rear brakes. By controlling the brake fluid pressure as the vehicle began to dive these devices helped control rear wheel lockup substantially but they were still limited because they affected both rear wheels equally. You really don't need to understand how proportioning valves and brake fluid limiting devices work but your mechanic definitely should before he or she repairs your braking system!

Several manufacturers went a step further by adding a rod and a rear brake proportioning valve to the rear of the vehicle. The image to the left is an example of that from Toyota. The rear brake proportioning valve limited the amount of brake fluis that could travel to the rear brakes as the vehicle tilted forwards. (peiods of heavy braking) The idea behind this was good because it compensated for worn shock absorbers and vaying loads. I can't tell you how many technicians have asked me what those rods were for. When I first saw them on cars in the 1970's it took me about 2 minutes to figure out what they did. You can clearly see the brake lines coming into them and the lines leading out to the rear wheel. There is a rod which leads to the body which travels with the body. These devices went a step further in controlling the difference between the front brakes and the rear brakes. By controlling the brake fluid pressure as the vehicle began to dive these devices helped control rear wheel lockup substantially but they were still limited because they affected both rear wheels equally. You really don't need to understand how proportioning valves and brake fluid limiting devices work but your mechanic definitely should before he or she repairs your braking system!

Anti-lock Braking Systems

Anti-lock braking systems were the answer to controllling the braking force applied to each wheel seperately. By using wheel speed sensors to keep track of how fast each wheel is turning and sending this information to the anti-lock brake module the module can determine which wheel is locking up. The module then sends a signal to the brake controller which then reduces the braking pressure to the wheel that is locking up. This all takes place very quicly as the system operates off a high speed bus network. Anti-lock brakes are now standard equipment on all vehicles. On September 1, 2013 the National Highway Traffic Safety Administration (NHTSA) mandated all vehicles sold in the United States had to be equipped with ABS. For more information on ABS systems click here.

For a list of all our automotive services click here

©Copyright 2026, Rock Bridge Automotive Repair

Design by Graphic Zoo and Responsee Team