Rock Bridge Automotive Repair

Anti-Lock Braking System Repairs In Gallatin TN

ABS Repairs- How Automotive Engineers Stopped Just One Wheel From locking Up!

After automotive brakes began to use hydraulic force to control the brake components the braking systems became very powerful. Shortly afterwards the automotive manufacturers began to use brake boosters to make the force required to activate the brakes require much less force. These changes allowed people who were not as strong physically the ability to apply enough force on the brake components to stop the wheels in a panic situation with much less foot pressure.

Be Careful What You Wish For

The modifications to the automobile opened up opportunities for many new drivers. With the additions of power steering and power brakes drivers didn't have to be as large and strong to drive cars anymore. Men, women, and younger children were able to drive. Almost everyone began to drive. The roads were still treacherous and accidents quickly began to end up with a lot of injured drivers and many fatalities.

In some cases it was found that making the brakes and steering so much stronger had it's pitfalls. In panic situations drivers were found to over-steer and over-brake. Several manufacturers began to implement devices to reduce steering power and braking power under certain situations. (The power steering achievements are covered on another page). Brake manufacturers began developing systems such as brake proportioning valves to limit the amount of brake fluid pressure that was applied to the rear wheels. There were many forms of brake pressure limiting devices and that did a great job of saving thousands of lives by preventing wheel lockup.

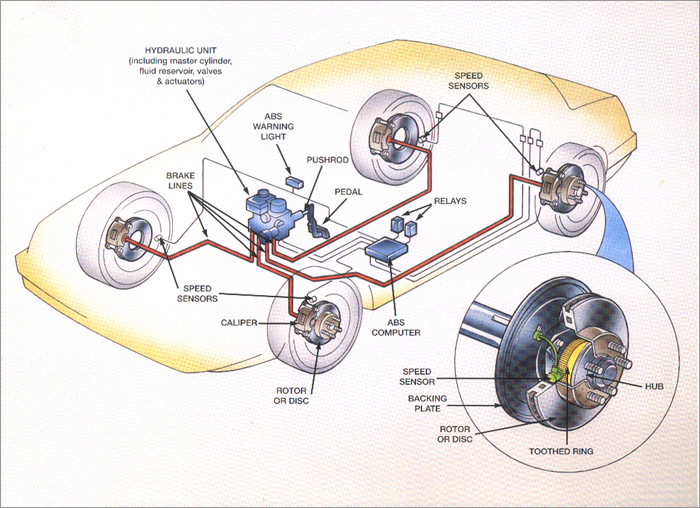

The problem with all of these devices was that they could only control the wheels in pairs, (either the front wheels or the rear). The engineers wanted to be able to stop the wheels individually. In order to accomplish this they needed to keep track of the speed of each wheel. This was accomplished through the use of wheel speed sensors, control modules and anti-lock brake valve assemblies. All of these components together are commonly called the Anti-lock braking assembly.

Putting the Anti-Lock Braking System Together

As you can see from the diagram below the Anti-lock Braking System is just that. A complete system which is designed to act as a conventional braking system, complete with brake proportioning controls, and as an anti-lock braking system during periods of wheel lock-up. Technicians repairing anti-lock braking systems need to be knowledgeable in all areas of the braking system. The brake master cylinder, the brake lines, the brake proportioning system, the disc brake system, the drum brake system, (some vehicles use the drum braking system for the rear brakes), wheel speed sensors, the brake control module, the wheel speed sensors, vehicle speed sensors, and the brake control valve assembly. Unless you plan to go to school for brake systems or to have less than the best brakes you should leave the diagnoses and repair of your Anti-lock Braking System to the professionals at Rock Bridge Automotive Repair. There is no better automotive repair shop in the Gallatin, Tennessee area to complete your Anti-Lock braking System Repairs than Rock Bridge Automotive Repair.

For a list of all our automotive services click here

©Copyright 2026, Rock Bridge Automotive Repair

Design by Graphic Zoo and Responsee Team